Turning

Åsco Metall AB

We manufacture using turning

Turning is an old craft and the most common method in Cutting processing. In turning, there are a number of different machining processes. You can read about who we work with below.

Longitudinal turning

When you have to turning details in medium to large series you usually use

longitudinal turning.

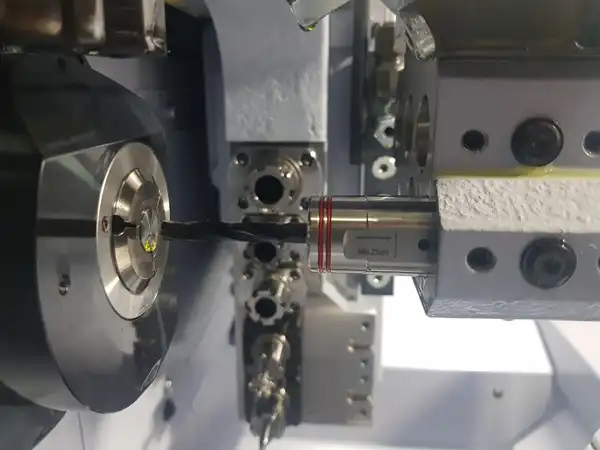

At longitudinal turning is the clamping sleeve that keeps the workpiece movable axially (i

longitudinal direction of the workpiece). This is how longitudinal turning differs from conventional

turning. However, the tool is radially movable (in the transverse direction of the workpiece). One

sleeve that supports and directs the material is located between the clamping sleeve and

the tools. This sleeve is called a steering sleeve.

The space between the tools and the guide sleeve is continuous and kept as short as possible. It is irrelevant how long the component is in longitudinal turning. By using a guide sleeve, radial stresses that can otherwise occur when rotating a long component are prevented.

Advantages of longitudinal turning

The advantages of longitudinal turning is many. One is the ability to turn long details. The guiding guide sleeve itself ensures that you do not experience the radial stresses that can otherwise occur when turning a long part. When turning parts in medium to large series, longitudinal turning is best suited, short cycle times and stable process.

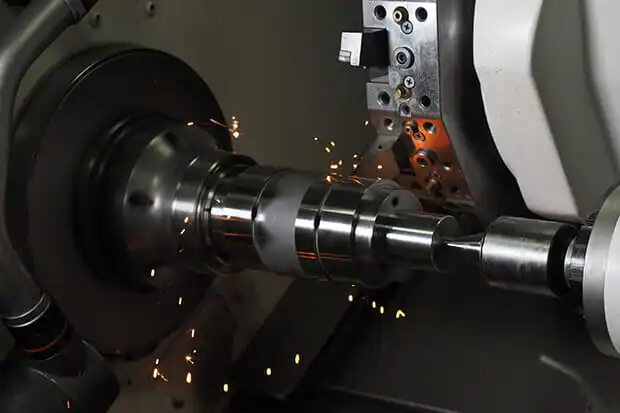

Automatic turning

Automatic turning is a machining process suitable for the manufacture of many

turned details that are identical in appearance in different metals and wood.

The production method of automatic turning and conventional turning is

identical, except that an automatic lathe completes each step automatically:

the component is turned, it is caught when it is ready and the lathe feeds new

material for detail number two. In an automatic lathe, the operator has been replaced by mechanics

which controls the movements of the tool

Curve-controlled automatic lathes are often described as completely mechanical. This indicates that

they are controlled by rotating, curved discs that move the levers. These move the tools in

appropriate pace and distance.

Today, servo motors managed by a computer program have often taken the role of

the curves. This provides more versatility. Previously, several manual adjustments were needed.

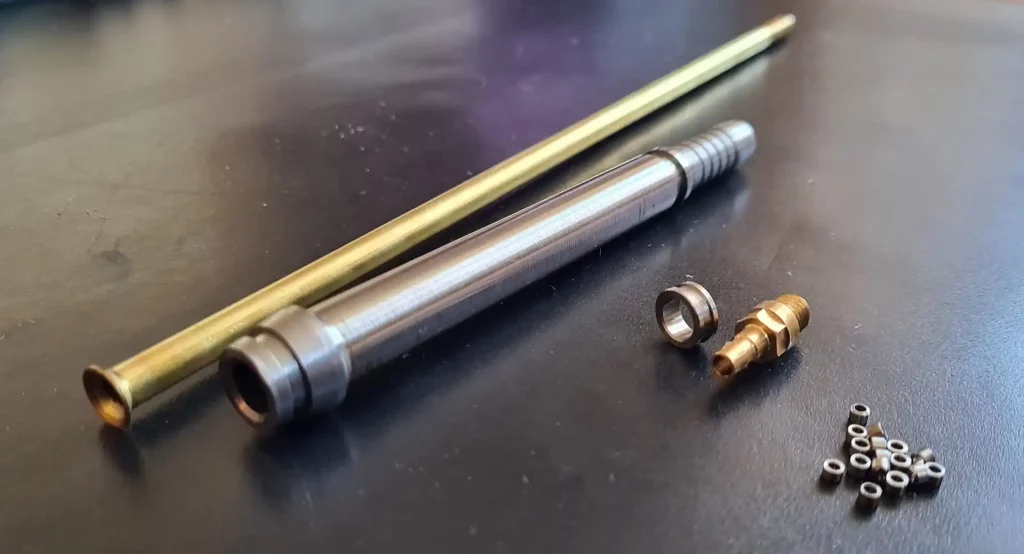

Turned details

The development at Åsco Metall throughout the year has led us to expand production to Cutting processing, where we have bought several length lathes.

Our capacity has thus increased significantly in which products we are capable of manufacturing.

Dimensions which we can turn your products are between ⌀1 mm up to ⌀32 mm where the length can theoretically be less than 1 mm to a meter long

The materials which our machine runs is primarily brass, structural steel and stainless steel, we also have experience with alloys with poor machinability.